Evaluation of an integrated microalgae-based biorefinery process and energy-recovery system from livestock manure using a superstructure model

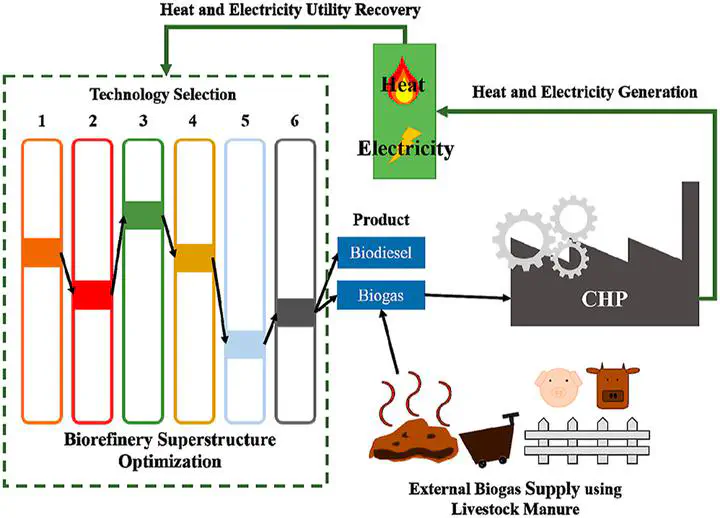

Graphical Abstract

Graphical AbstractAbstract

Microalgae based biofuel has been identified as a promising renewable energy source, which is capable to address the climate change with the replacement of non-renewable energy source that leads to serious environmental impact. Therein, a biorefinery integrated with resource-recovery process which targeting biofuel productivity was designed along with a comparative case study to evaluate system performance considering both environmental and economic aspects. Such integrated system comprised of four objectives:1) technological pathway optimization to maximize net operating margin (NOM), 2) resource recovery to recycle bioresidue produced from biorefinery, 3) utilization of external biowaste (e.g., livestock manure) to increase efficiency of the energy-recovery process, and 4) an overall evaluation on greenhouse-gas (GHG) emissions. The proposed model was applied to a case study in Incheon, South Korea, where has massive microalgae cultivation area. The base case has compared two main upgrading options including conventional transesterification and the emerging technology of hydrothermal liquefaction (HTL). As per result, HTL has better performance of NOM and GHG emissions with the value of 8982 US$ and 15,567 kg CO2-eqv, respectively while comparing to transesterification. Ultimately, the subcase that involve with energy-recovery by the utilization of bioresidue and livestock manure (HBOW) has shown great improvement which NOM is increased by 20% while the GHG emissions are reduced by 96%. In short, HTL is economically and environmentally feasible for the biofuel upgrade from microalgae. A sensitivity analysis has been carried out which suggesting HBOW would yield the highest NOM of 14,171 US$ with 40% increase of microalgae amount from the origin, and the NOM would have definite increase with the extra input of livestock manure.