Biography

beep-boop

Hello world 👋 This is Juin Yau Lim (林俊耀).

I am interested on providing sustainable solution to complex engineering problem with my substantial background in Chemical Engineering (M.Eng) and Environmental Engineering (PhD). Devoted to bridge the gap between research and industry.

You can find my publications, recent post, and one page résumé in this webpage.

If you have more time, feel free to read my full CV!

Fun-fact:

- Enjoy playing with numbers aka Data Analytics. 📈

- Juggling around AI, modeling, and optimization. 🖥️

- Polyglot, proficient in multiple languages. Try me! 🗣️

- 100% Cat friendly 🐱

Never the smartest mind in class but always the one not afraid of trying new things.

Thanks for spending time to understand me! Ciao

- Renewable Energy

- Process System Engineering

- Artificial Intelligence

- Waste-to-Energy

- Environmental Management

PhD in Applied Environmental Science and Engineering, 2023

Kyung Hee University (Global)

M.Eng in Chemical Engineering & Environmental Engineering, 2018

University of Nottingham

Recent Posts

Featured Publications

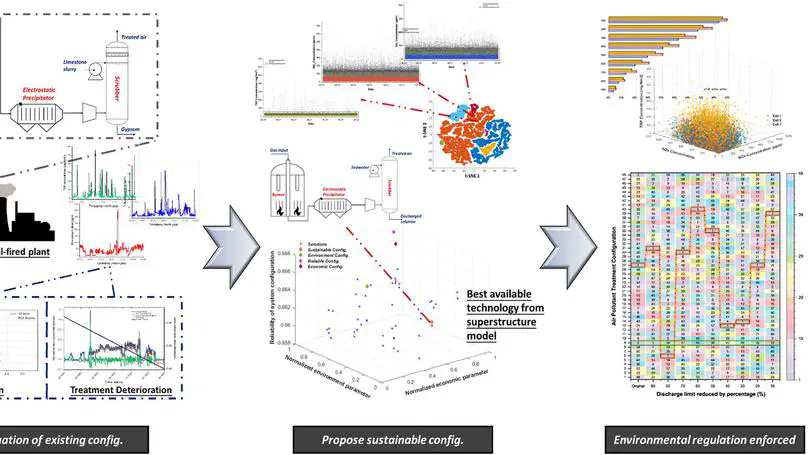

Conventional fossil fuels are relied on heavily to meet the ever-increasing demand for energy required by human activities. However, their usage generates significant air pollutant emissions, such as NOx, SOx, and particulate matter. As a result, a complete air pollutant control system is necessary. However, the intensive operation of such systems is expected to cause deterioration and reduce their efficiency. Therefore, this study evaluates the current air pollutant control configuration of a coal-powered plant and proposes an upgraded system. Using a year-long dataset of air pollutants collected at 30-min intervals from the plant’s telemonitoring system, untreated flue gas was reconstructed with a variational autoencoder. Subsequently, a superstructure model with various technology options for treating NOx, SOx, and particulate matter was developed. The most sustainable configuration, which included reburning, desulfurization with seawater, and dry electrostatic precipitator, was identified using an artificial intelligence (AI) model to meet economic, environmental, and reliability targets. Finally, the proposed system was evaluated using a Monte Carlo simulation to assess various scenarios with tightened discharge limits. The untreated flue gas was then evaluated using the most sustainable air pollutant control configuration, which demonstrated a total annual cost, environmental quality index, and reliability indices of 44.1 × 106 USD/year, 0.67, and 0.87, respectively.

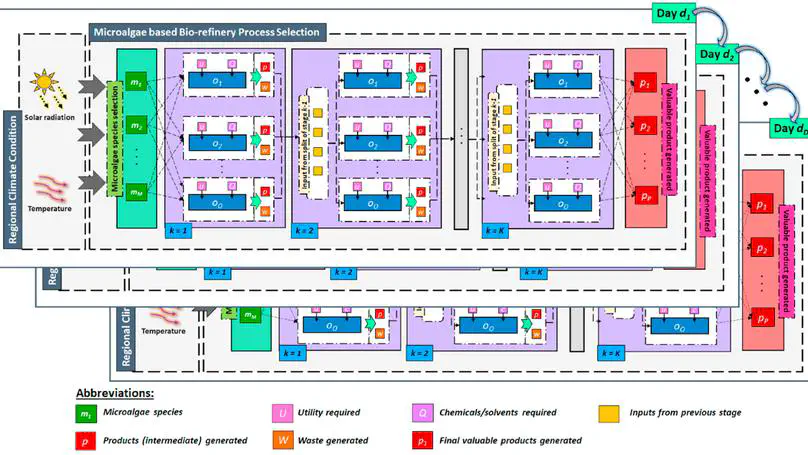

An emerging renewable energy source from living organisms, microalgae are recognized for its remarkable energy content and continuously receiving interest with a great potential in increasing its shares in fuel market. The main challenge for stable biorefinery operation is cultivation, given that the growth of microalgae is highly dependent on climate conditions, especially ambient temperature, and solar exposure. Herein, an advanced forecasting algorithm predicts daily climate conditions a year ahead. The forecast is then used in a dynamic metaheuristic optimization framework to determine optimal microalgae biorefinery process pathways with promising total annual margins and greenhouse gas emissions. In return, the optimal solution is reported with a total annual margin of 815,716 US$/y and greenhouse gas emission of 1.1 × 107 kg CO2-eqv/y. The most feasible microalgae species among the selection pool are identified in terms of kinetic growth, which is attributed to the climate behavior of the selected case-study region. A scheduling scheme is then identified for the optimal harvest period of cultivated microalgae. Next, uncertainty analysis for the selected process configuration is conducted using Monte Carlo simulation to investigate how variations in climate conditions will affect its overall performance. Additionally, the process is further enhanced by including renewable electricity sources which allow reducing 50% greenhouse gas emissions with the configuration of biomass energy (1.2%), solar power (0.1%), and wind energy (98.7%). In summary, this study provided a comprehensive guidelines on strategically deploying large scale microalgae biorefineries considering its long-term operational sustainability abiding the possible uncertainties within the system proposed.

Recent Publications

Contact

- limj@anl.gov

- Illinois, 60439